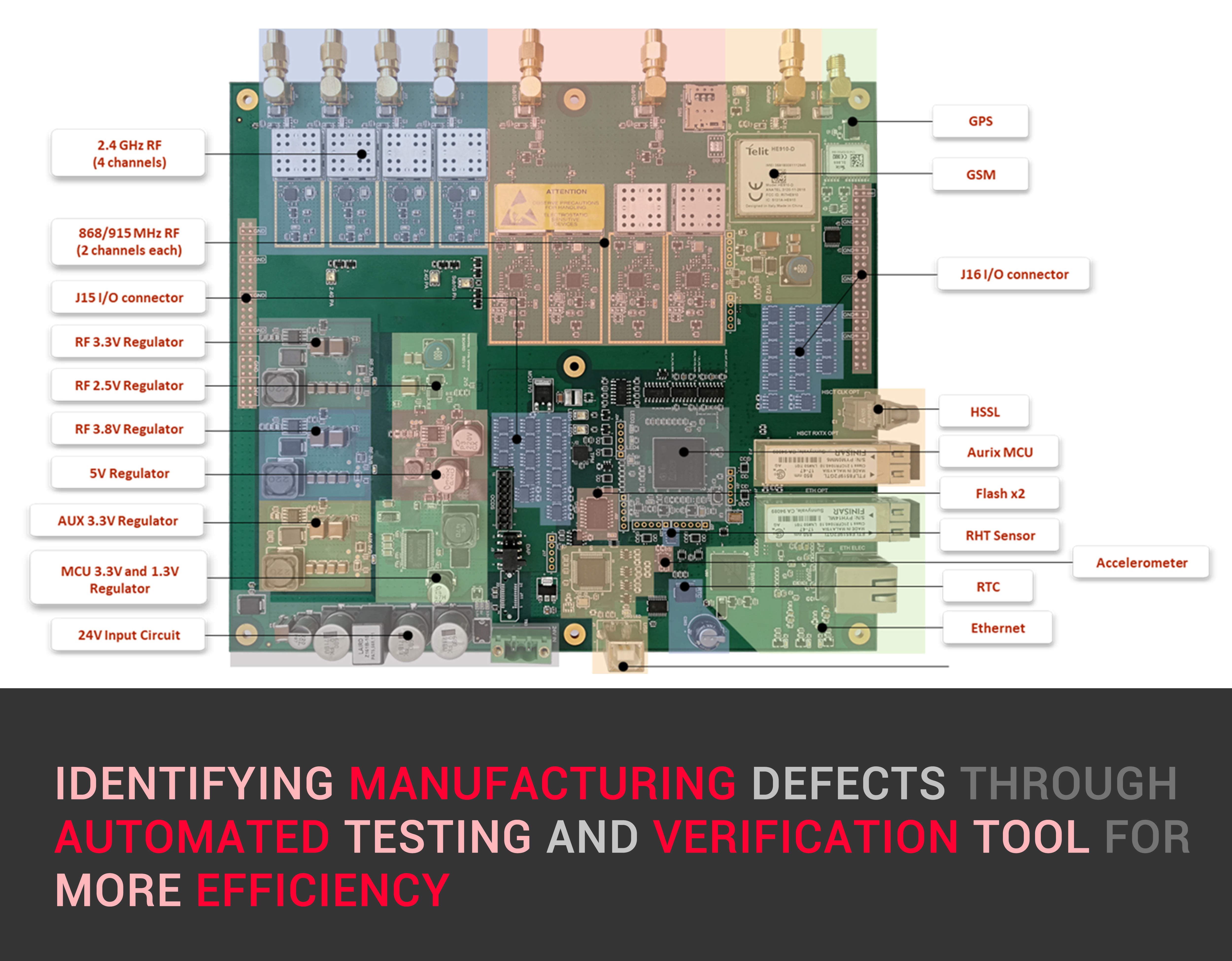

It’s difficult to manually test the PCBAs produced on a production floor, considering the timing constraints of the projects and keeping the production yield in focus. Automated PCBA inspection solutions not only help the production team eliminate the risk of sending PCBAs to the customer but also adds efficiency to the customer’s product and lowers the failure rates by using the bad PCBAs. Our automation team developed a tester that enables the user at the production floor to quickly identify the failures on the PCBAs that might occur due to component, production line, operator, or any abnormality of the production process. Manual Visual Inspection (MVI) is mostly carried out for the produced PCBAs. However, this method of PCBA inspection is not sufficient to identify the defective components, missing parts, open or short paths, or any manufacturing defects that affect the quality and reliability of the produced PCBAs. Our automation team offers a complete Functional Verification Testing (FVT) for the PCBAs.

How we do it?

- Carry out the Functional Verification Testing at different layers or blocks.

- Identify functional modules on the board.

- Develop the test plan and test cases.

- Develop the test JIGs.

- Develop the test scripts.

- Execute the verification and validation steps for the identified functional blocks using automation engine.

- Generate test reports for user analysis.

Key Benefits

- Improved Quality

- Improved Reliability

- Reduced testing time

- Impact analysis of failures

- Test coverage enhancements

- Regression testing

Our Tools